Oil & Gas

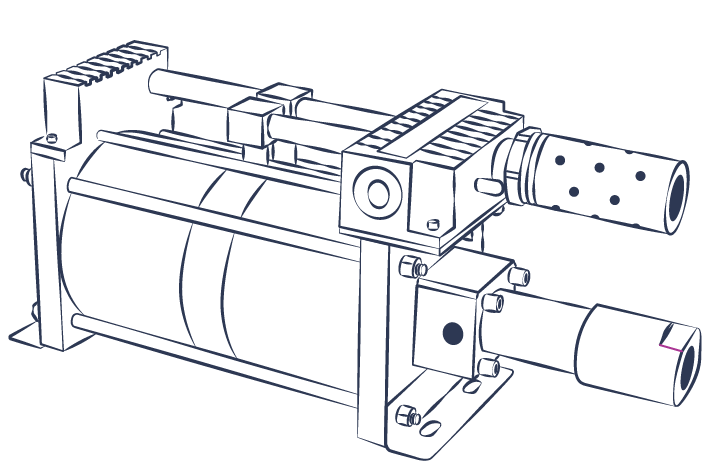

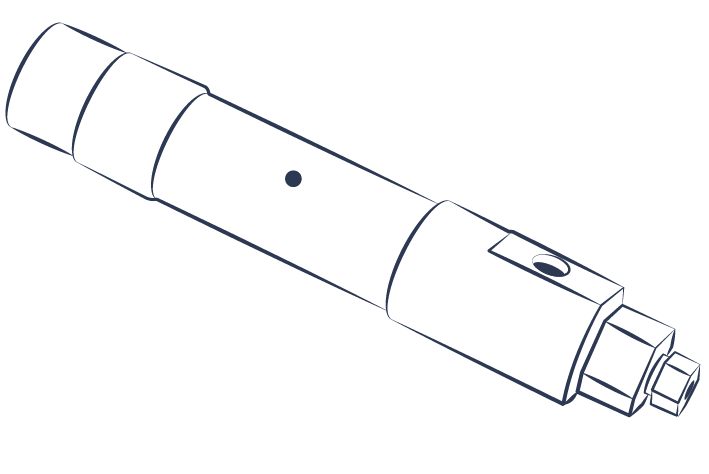

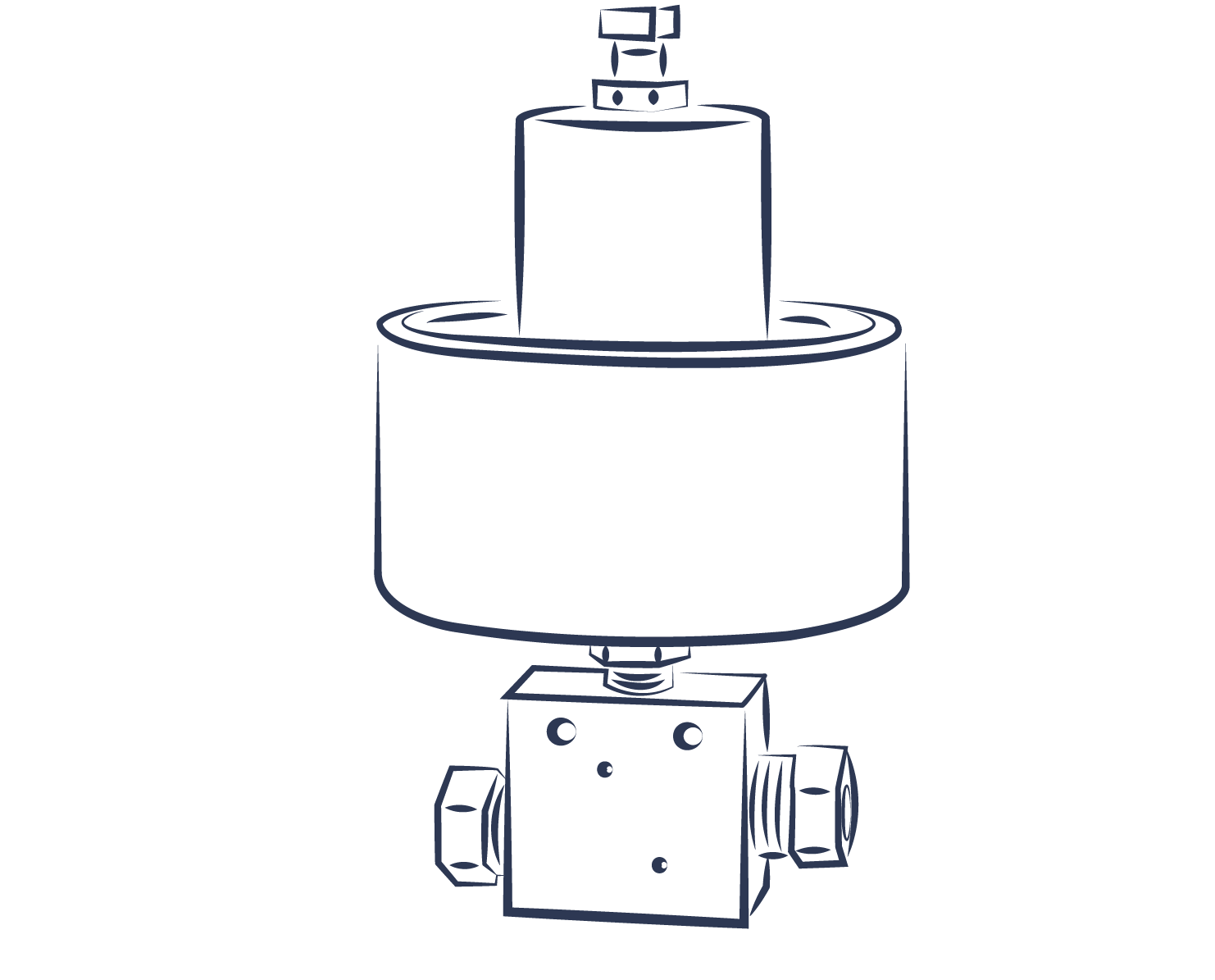

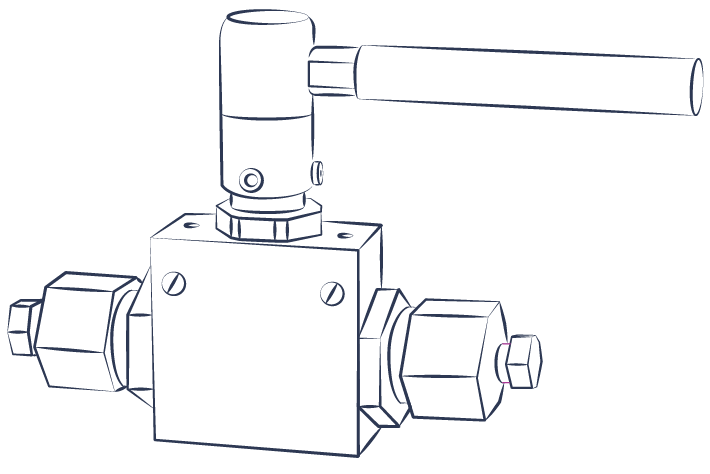

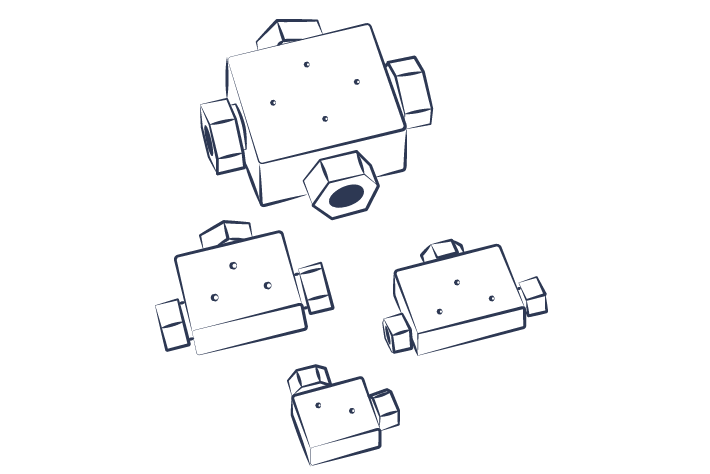

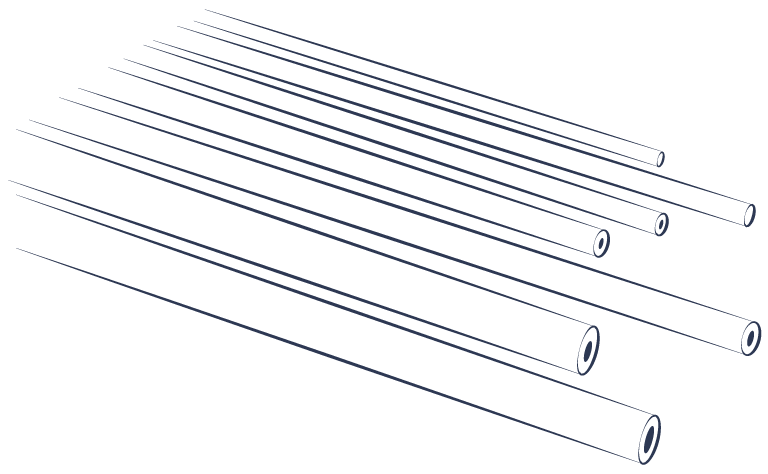

High pressure components for Oil & Gas industry

In the context of installations within the Oil & Gas sector, safety is an absolute priority. Components such as high-pressure pipes, valves and fittings must meet rigorous safety requirements in an industry known for its potential risks. It is essential that manufacturers of such components have advanced testing systems to ensure they meet the technical specifications required by this highly specialized sector.

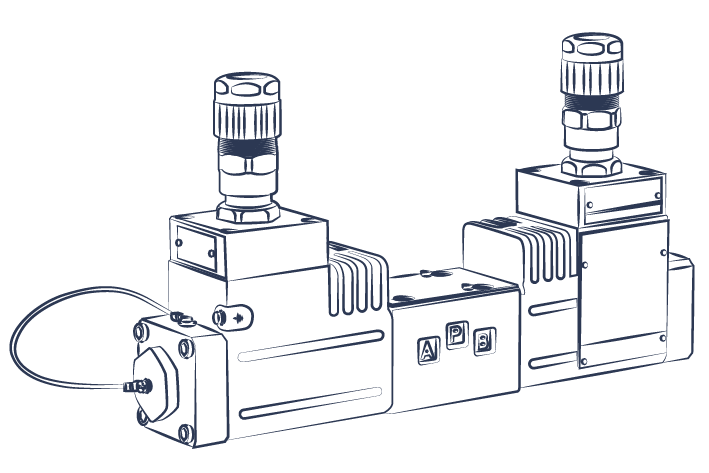

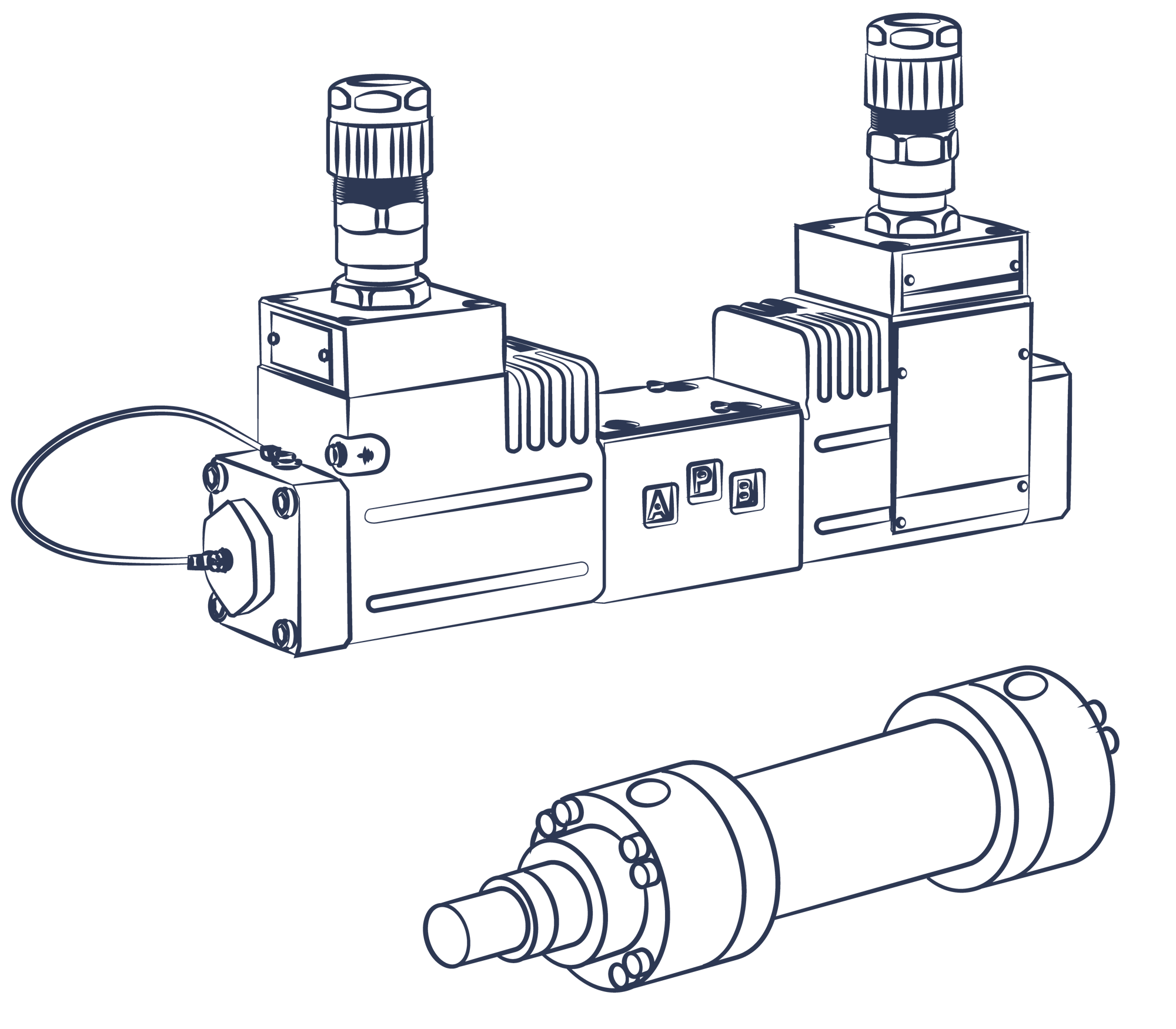

Interfluid has built a strong expertise in the high-pressure field since 2005, allowing us to provide valuable technical support to companies operating in this sector. Our technicians are capable of offering detailed comparisons between components from different brands and, even more importantly, designing and sizing customized pressure generation units. This means we can optimize solutions based on the specific needs of our customers and the regulations that must be met.

In line with the evolution towards Industry 4.0, our approach can be integrated with advanced control systems and PLCs (Programmable Logic Controllers) to ensure efficient and safe management of pressure generation units. Besides providing high-quality components, we are reliable partners who can actively contribute to the design and commissioning of customized pressure systems for the oil and gas industry. Our mission is to ensure that every component and system we offer is perfectly tailored to the specific safety and performance needs of our customers.