Pneumatic vacuum generatorssingle-stage, multi-stage, and multifunctional

Pneumatics, Vacuum, and Lubrication

Applications

- Industrial robotics

- Woodworking industry

- Food industry

- Plastics and rubber industry

- Glass industry

- Ceramics industry

- Printing/Paperboard industry

Description

The operation of single-stage vacuum generators is based on the Venturi physical principle.

In general, vacuum generators are powered with a pressure of 6 bar. The vacuum generator range includes a Low-Pressure version that allows excellent performance with compressed air supply at lower pressures (up to 4 bar), enabling significant energy savings.

It is possible to equip the vacuum generators with a high-sound-reducing silencer, which is installed on the R discharge connection.

Single-stage vacuum generators are made of anodized aluminum (ejectors in brass or aluminum).

Features

- Suction capacity from 1 to 20 m³/h

- ltimate pressure up to 100 mbar abs

Advantages

- Easy cleaning

- High emptying speed

- Quick and efficient work cycles

Multi-stage vacuum generators produce a maximum depression of 90% and have various suction capacities. The compressed air supply pressure ranges from 1 to 6 bar.

Multi-stage generators utilize the kinetic energy of the compressed feeding air by passing it through a series of appropriately sized ejectors before releasing it into the atmosphere. This system allows for a lower consumption of compressed air, at the same flow rate, compared to single-stage vacuum generators.

Some families of multi-stage vacuum generators also have a Low Pressure version that allows excellent performance with compressed air supply at lower pressures (up to 4 bar), enabling significant energy savings.

To reduce maintenance interventions, it is important to implement a good filtration of both the compressed and aspirated air.

Features

- Suction capacity from 3 to 750 m³/h

- Ultimate pressure 100 mbar abs

- They can be used in potentially explosive atmospheres with compressed air supply only

- They can be used in environments with variable temperatures from -20 to +80 °C

- Made of anodized aluminum (with ejectors and stainless steel screws)

- Sealing gaskets and flap valves in EPDM or VITON on request

Advantages

- High quietness and possibility of continuous use (without heat development) due to the absence of moving parts

- Small size, light, compact, and space-saving in relation to their large suction capacity

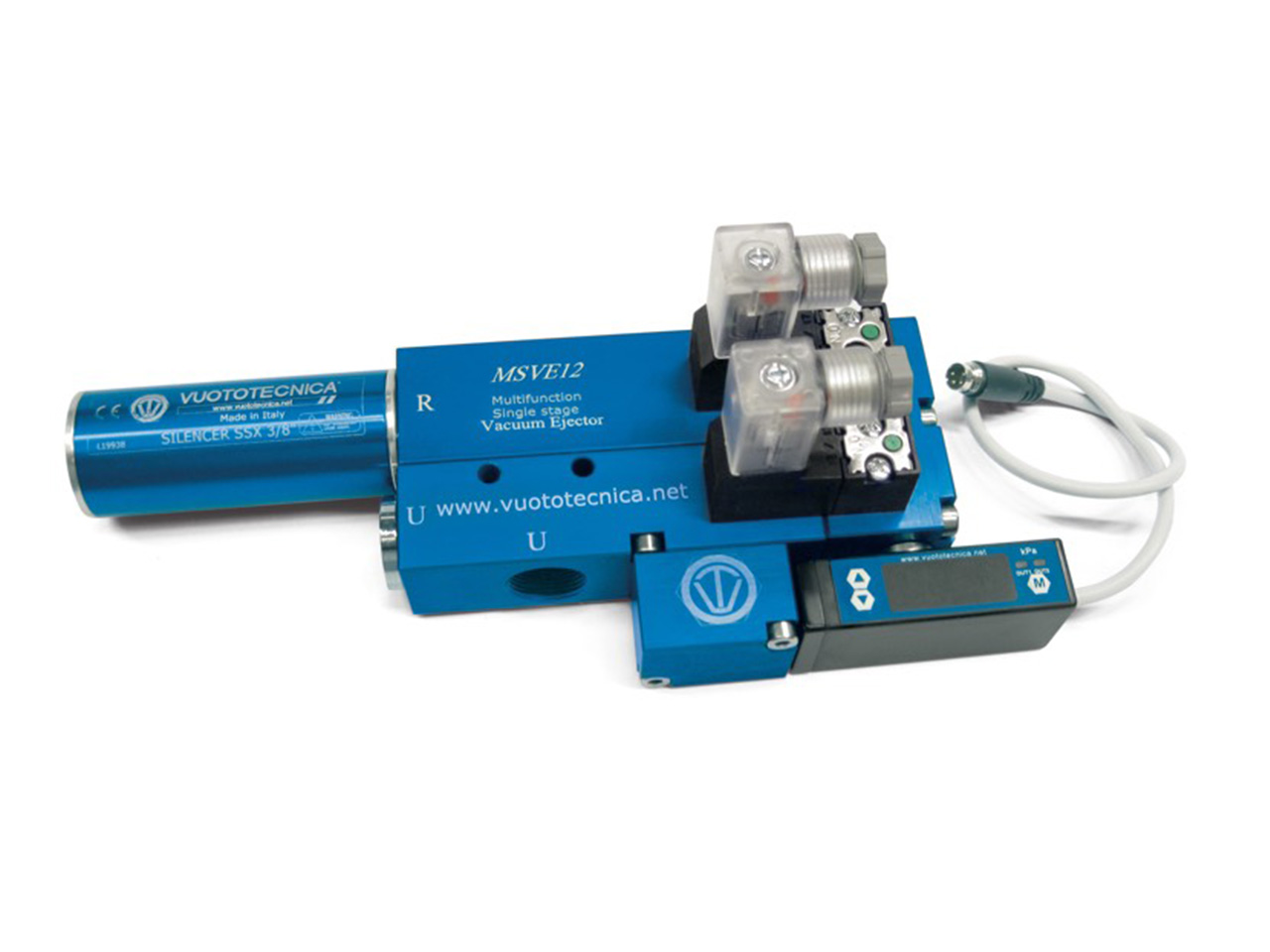

The single-stage and multi-stage generators can be multifunctional by assembling:

- A micro solenoid valve that supplies compressed air to the generator

- A micro solenoid valve for blowing out the compressed air

- A flow regulator essential for dosing the exhaust air

- A digital vacuum switch with a display and LEDs that indicate the switchings to manage the supply of compressed air and provide a signal for safely starting the cycle

Operation

By activating the micro solenoid valve for compressed air supply, the generator begins to create the required vacuum. When the maximum specified value is reached, the vacuum switch interrupts the supply of compressed air to reduce energy consumption.

In this way, the vacuum level is maintained within the predefined safety values (hysteresis), allowing significant compressed air savings. A second signal from the vacuum switch, also adjustable and independent of the first, can be used to start the work cycle when the achieved vacuum level is appropriate for use.

At the end of the work cycle, the air-feeding micro solenoid valve deactivates, and simultaneously, the exhaust micro solenoid valve activates to quickly restore atmospheric pressure for further use.

Are you interested in our products?

Register to Fluid-Hub.net, the digital portal for our products.

Buy directly online and get an additional 2% discount and many other benefits!

Choose the vacuum generator you need and go directly to Fluid-Hub.net

| Series | Average stock | Discover online availability |

|---|---|---|

| MSVE | 🚚 Orderable from supplier | ⌛ Available soon |

| GVMM | ✅ Usually available | ⌛ Available soon |

| PVP | ✅ Usually available | ⌛ Available soon |

| M | ✅ Usually available | ⌛ Available soon |

| PVP large capacity | 🚚 Orderable from supplier | ⌛ Available soon |

Download

- Vuototecnica catalogueDownload Vuototecnica catalogue

Why Your Fluid Mate?

Presence in the territory

Automated warehouse

To monitor the order flow with precision, accuracy and speed

Wide range of products

We offer you multiple alternatives to quickly meet your request

Specialized technical support

We study the comparisons with other brands and provide support for your project

Assembly and testing of pneumatic panels

We design, draw, assemble and test control pneumatic panels

E-commerce

To learn more

Pneumatics • 2 August, 2024

Vacuum generators: how they optimize industrial production

Vacuum generators are indispensable tools in numerous industrial sectors due to their ability to enhance the efficiency and quality of production processes. These devices find applications in various fields, from the processing of chemical and cosmetic products to the production of food and beverages, and their ability to handle products gently makes them an essential component for many companies.