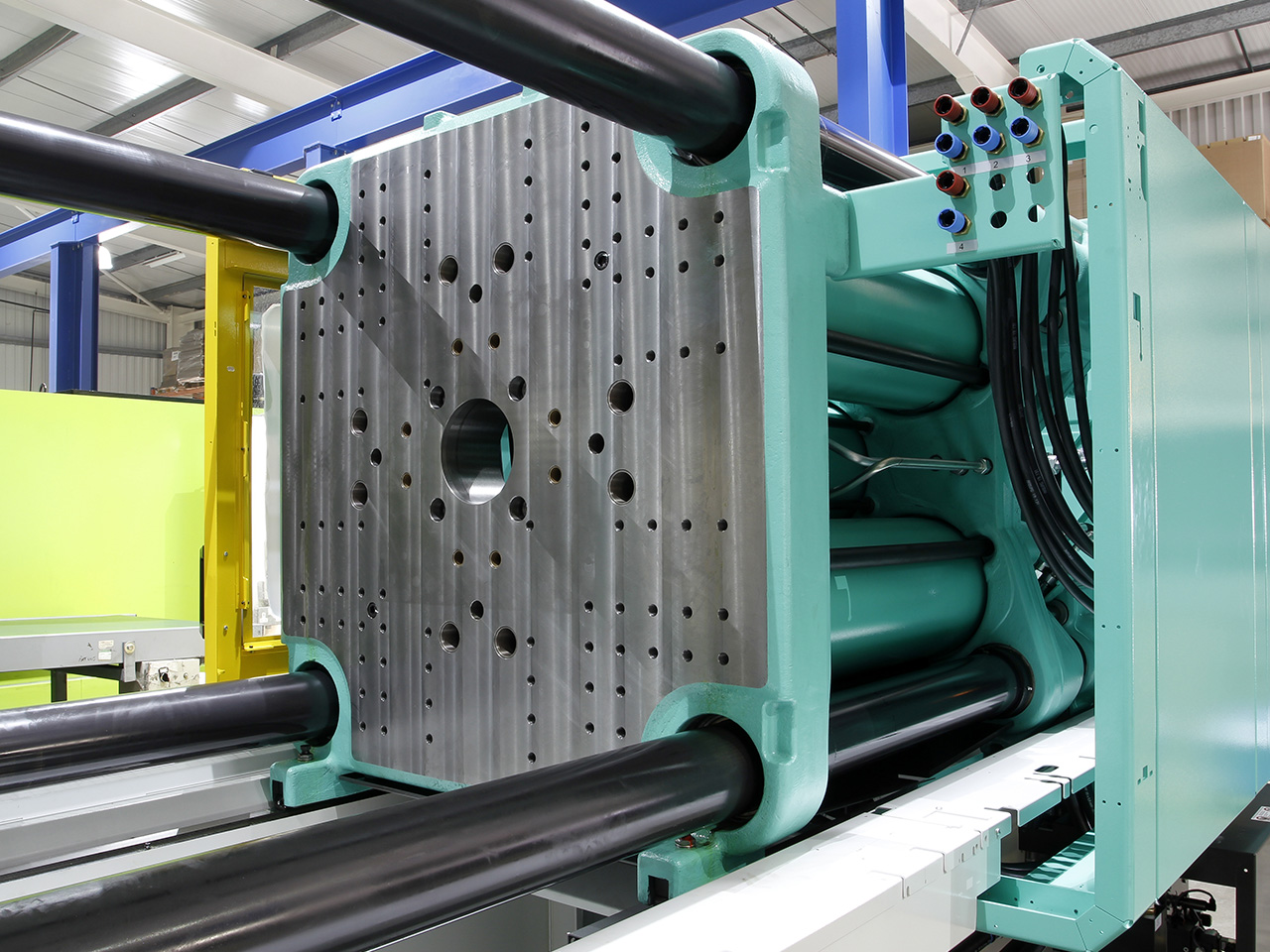

Plastic and rubber injection moulding machines

Hydraulic components for plastic and rubber injection moulding machines

In the plastic moulding sector, energy efficiency plays a crucial role, considering that energy-related costs constitute a significant portion of overall company expenses. Within this context, product competitiveness can greatly improve through the reduction of energy consumption by machines, resulting in a substantial decrease in operating costs for companies in this industry.

Understanding this need completely, Interfluid has dedicated time and resources to develop customized solutions for optimizing energy efficiency in plastic and rubber injection molding machines. Leveraging our extensive experience and technical expertise, we can design tailored energy-saving systems, adapting them to the specific needs of manufacturers and maintenance personnel responsible for plastic presses.

We don't limit ourselves to customized design, we also offer standardized servo pump solutions that help reduce the costs of revamping existing machinery while simultaneously enhancing energy efficiency. Additionally, we commit to delivering the necessary hydraulic components swiftly, thanks to our extensive in-stock inventory.

Why Your Fluid Mate?

Sizing of customized energy saving systems

Technical assistance

Technical comparisons

Wide range of products

To learn more

Improving industrial machinery efficiency through hydraulic oil contamination monitoring