Die casting

Hydraulic components for die casting machines

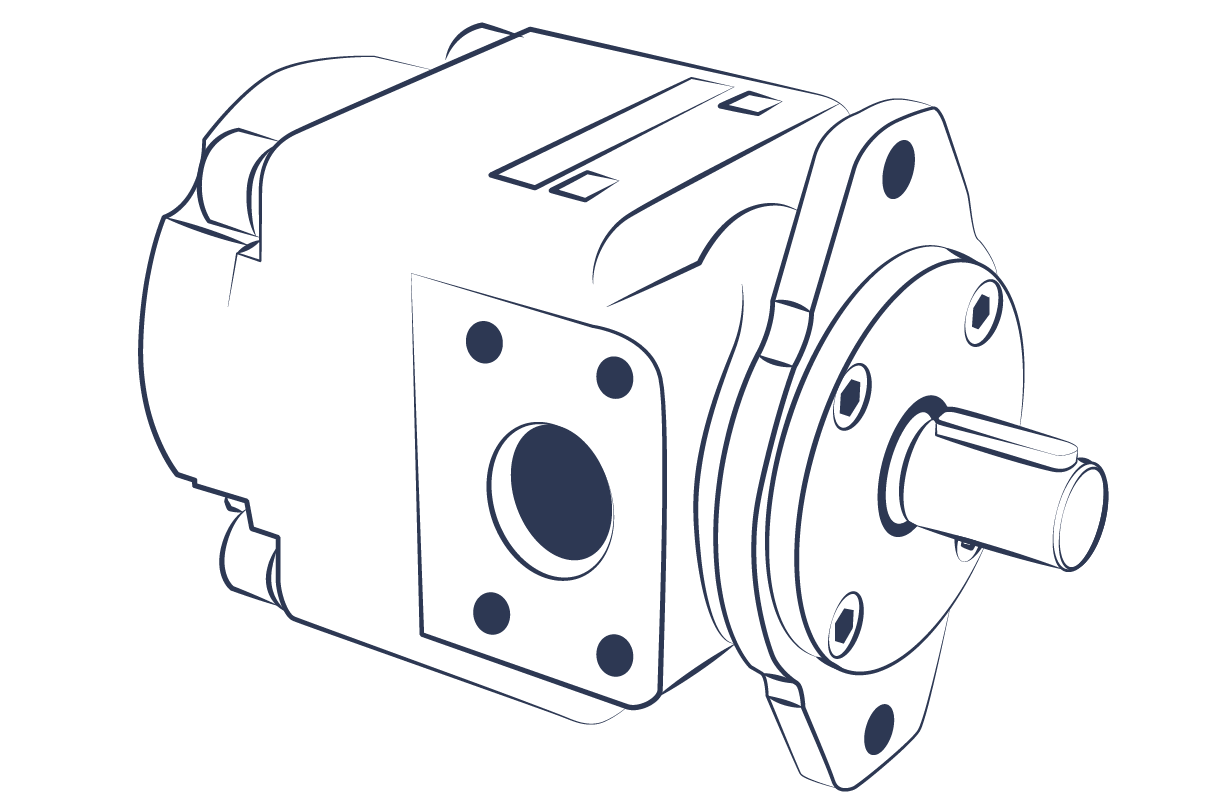

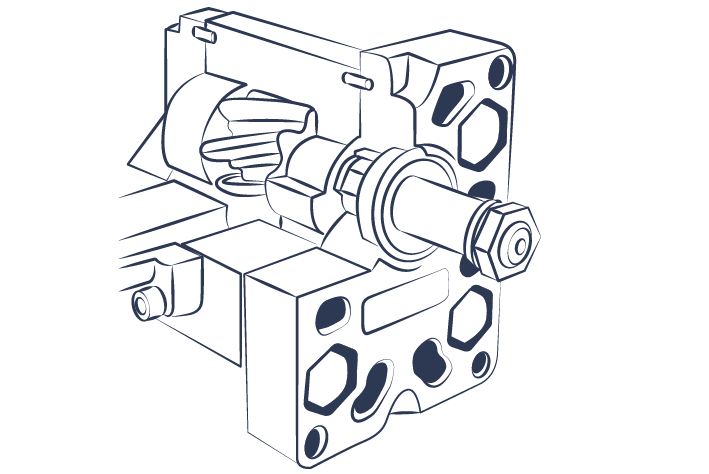

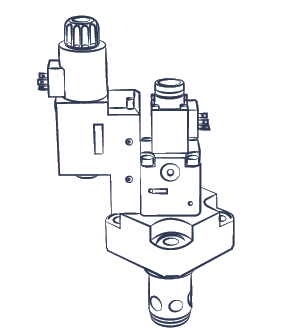

Die casting technology is characterised by a high consumption of energy required, for example, to activate automation processes or bring to high temperatures the metal to be injected into the mould during the die casting phases. The moulding machines must ensure extreme reliability, repeatability and precision, necessary, for example, in the phases of closing the mould or finishing the processing with trimming presses. These are always processes with a high wear potential of components that must withstand high pressures and temperatures in repeated cycles. Interfluid distributes directional and proportional flow control valves, vane pumps, internal gear pumps that have been tested over the years by numerous customers. Together we have selected the most suitable components for the needs of die-casting processes, obtaining positive feedback.

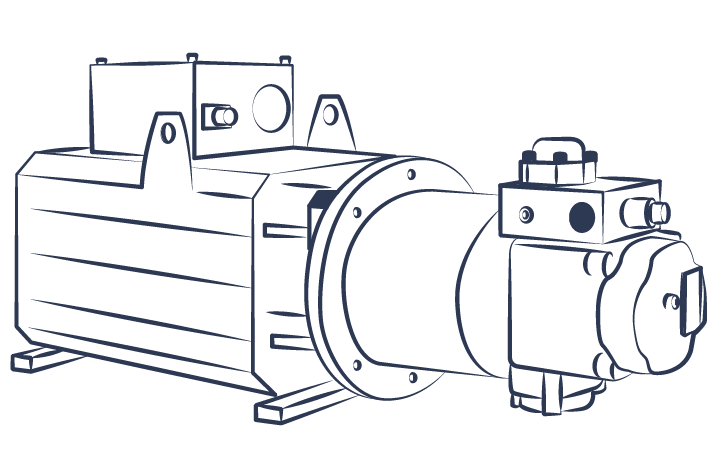

For the field of trimming presses, we have also studied customized solutions with servopumps that allow to reduce the oil temperature thanks to the lower average speed of the pump, and consequently, to reduce the amount of energy required for cooling the hydraulic system.

Why Your Fluid Mate?

Sizing of customized energy saving systems

Technical assistance

Analysis of the technical requirements according to relevant regulations and fluid deployed

Technical comparisons

Experience acquired