Jet grouting

Hydraulic components for jet grouting

The technology of jet grouting involves the injection of high-speed water and cement mixtures into the subsurface.

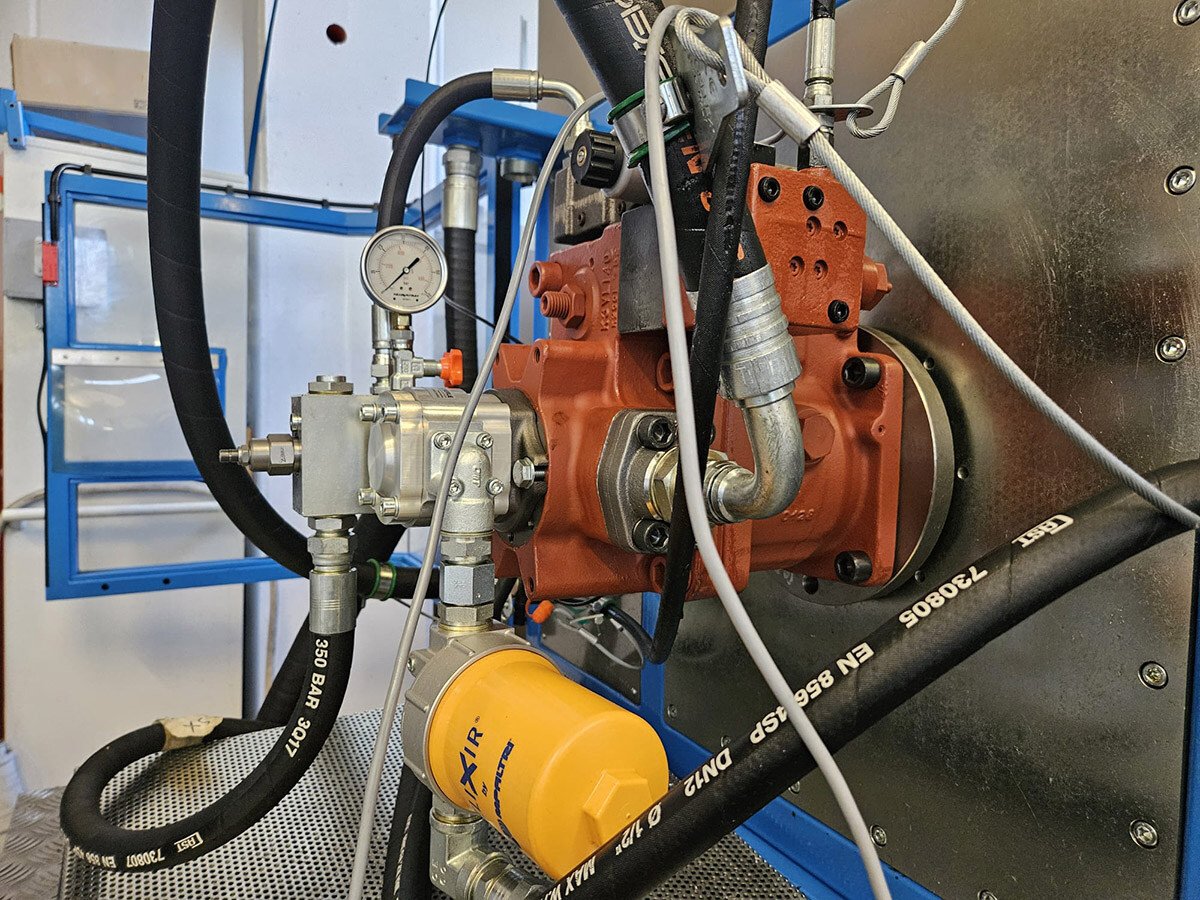

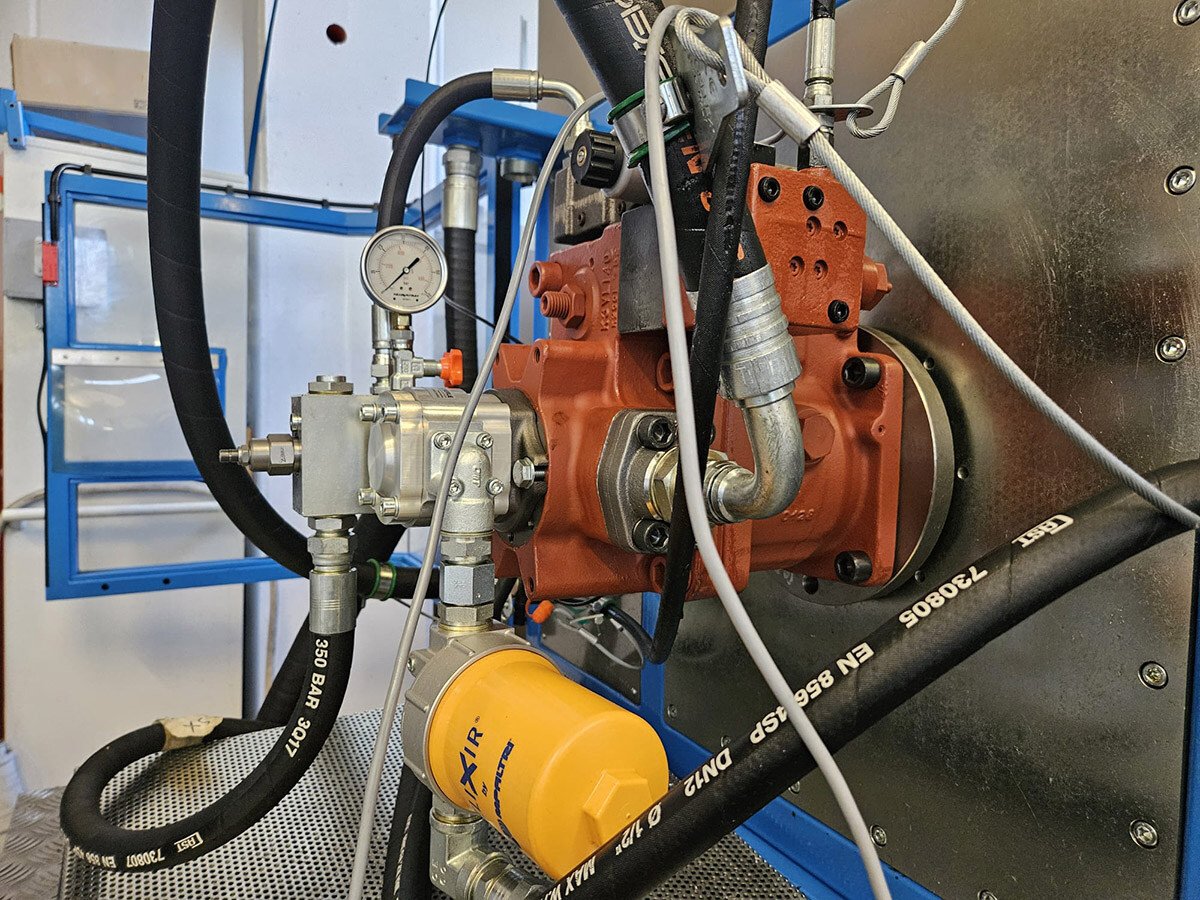

In this type of machinery, hydraulics are essential for optimizing the injection cylinder's control. The injection cylinder can be effectively controlled through the use of variable displacement piston pumps and proportional flow and pressure control valves, selected and distributed by Interfluid.

Furthermore, Interfluid has developed solutions to help manufacturers enhance the performance and lifespan of these types of machines, providing customized solutions (package solutions: pumps, valves, filters, couplings, accessories).

Why Your Fluid Mate?

Technical consultation

Analysis of your needs for selecting the most suitable components

Customized settings

Even with standardized servopump solutions to reduce revamping costs

Alternative products

If the components are obsolete, we offer alternative solutions

Wide range of products

Including quality-tested alternative brands

To learn more

Predictive Maintenance in Hydraulic Systems: How Particle Counters Make a Difference

Preventing failures and machine downtime is a top priority in any industrial sector, and hydraulic systems are no exception. Often the heartbeat of ...

Improving industrial machinery efficiency through hydraulic oil contamination monitoring

According to studies effected by MP Filtri, about 75% of hydraulic circuit breakdowns are caused by fluid contamination. Their number may be ...