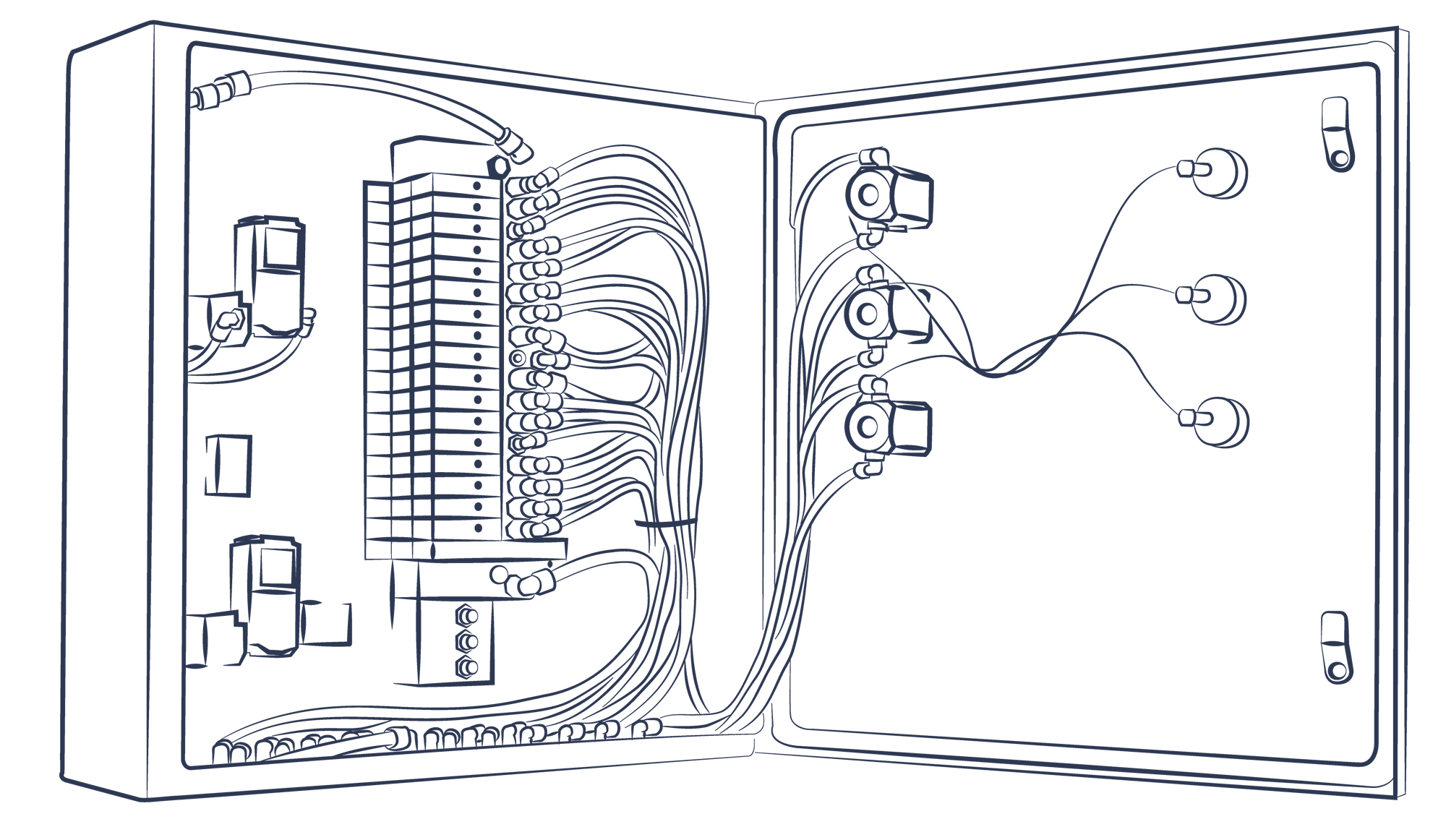

Plastic and rubber extrusion

Applications of pneumatic components for the plastic and rubber extrusion

The rubber/plastic industry, particularly the extrusion process, is an integral part of various industries involved in the production of multiple products of the same nature or similar materials. Specifically, the extrusion technique is the procedure for shaping plastic or metallic materials (generally those with high plasticity). This occurs through a continuous process in which the material is melted by the action of a screw inside a heated cylinder. Finally, it is passed through an extrusion head or die to obtain the desired shape before cooling.

Interfluid plays a key role in this sector, operating along the entire production chain (from extrusion to thermoforming, heat sealing, converting, presses and packaging). We support customers at every stage, ensuring advanced and automated management during the processing of plastic films.

The integration of pneumatics and vacuum technologies into our services allows us to precisely manage every detail of the production process, contributing to the success and efficiency of our customers' operations in the rubber industry.

Why Your Fluid Mate?

Technical consulting

analysis of the hydraulic circuits for the choice of the best performing components

Customized calibration

Alternative products

Wide range of products

To learn more

Improving industrial machinery efficiency through hydraulic oil contamination monitoring