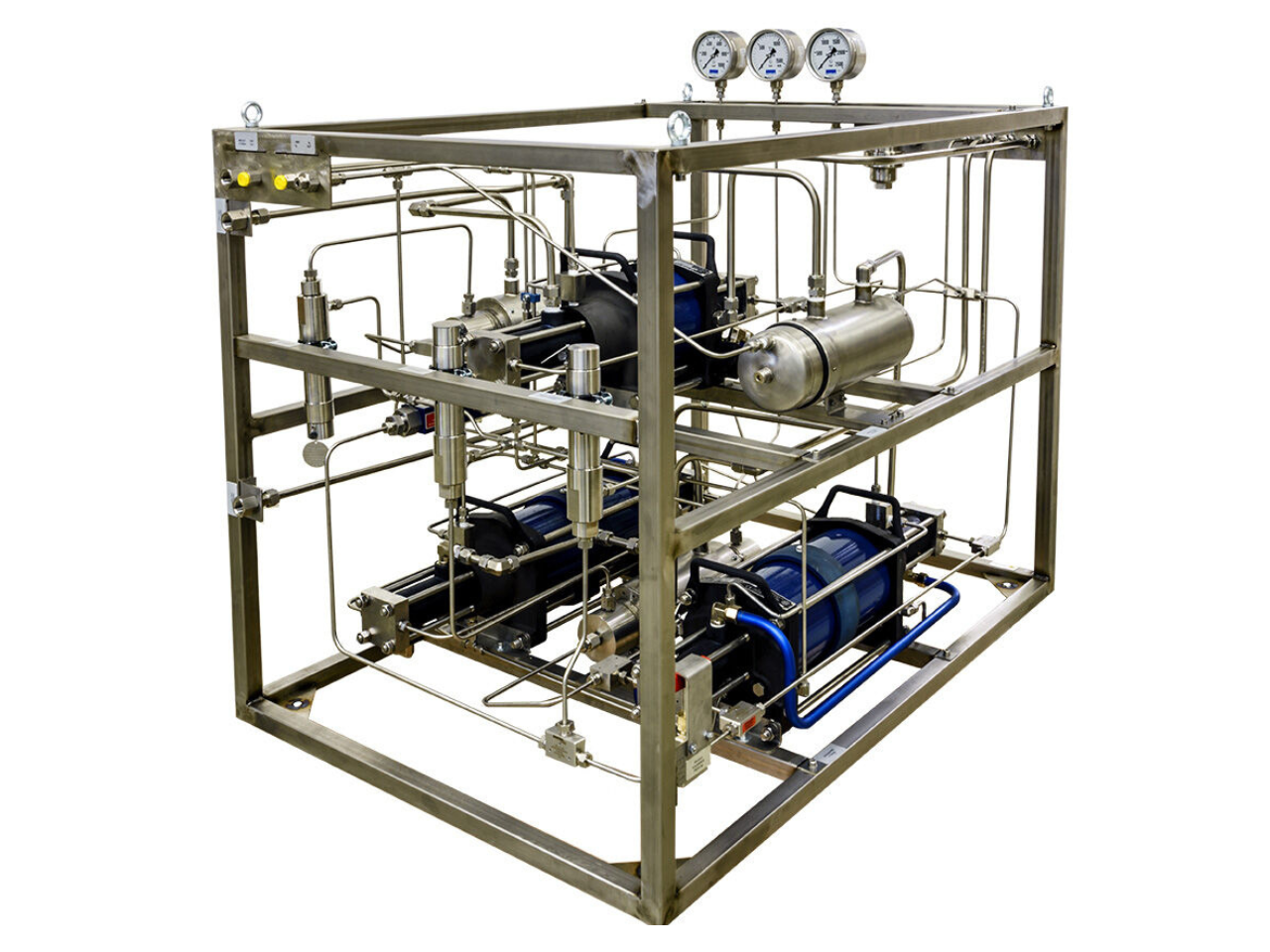

Units for pressure testing with gas and air driven multiplierMaximum working pressure up to 30.000 psi (2069 bar)

High pressure

Applications

- Hydrogen and technical gases

- High-pressure gas testing of valves, fittings, pipelines, cylinders and tanks

- Leak testing with helium

- Mechanical seals

- Accumulator charging

- Airbag testing

- Gas transfer

- Gas injection (foaming)

- Gas cylinder refill

- Tyre inflation

Description

Interfluid designs and builds wide range of unit for pressure testing with gas and air driven multiplier for gas transfer and charging of cylinders and accumulators with air, nitrogen, helium, oxygen and hydrogen. The main benefit of these systems is that they don’t require an electrical connection and lubrication. These units are complete of required controls and instrumentation needed to manage the pressure and flow downstream of the gas booster.

Available options:

- Data acquisition with PLC or manometer

- Pressure gauge diameter 150 mm, scale based on pressure

- Isolation valve

- Piped exhaust of drive motor and gas section

- Trolley version, mounted with wheels

- Dual version booster (ideal for low pre-charge)

Features

- Max working pressure: 30.000 psi (2069 bar)

- Open tubular frame in stainless steel

- Also available in AISI version (to be corrosion resistant even in offshore environment)

- Pressure regulation, filtration and lubrication unit for drive air

- Maximum allowed drive air pressure: 150 psi (10 bar)

- Drive air safety relief valve

- Gas filter to the gas booster

- Gas inlet pressure gauge

- Pilot valve minimum inlet pressure upstream with automatic stop of the unit, setting to be agreed

- Pilot valve maximum outlet pressure downstream with automatic stop of the unit, setting to be agreed

- Relief valve for maximum outlet pressure downstream, setting to be agreed.

- Pressure relief valve

- Pressure gauge diam. 100 mm, scale based up to 36.000 psi (2500 bar)

- Outlet gas connection based on pressure downstream

Advantages

- Compatible with almost all gases, including hydrogen

- Pressure maintenance without any energy consumption

- Automatic restart in case of downstream leakage

- Adjustable stall pressure

- Ideal for START/STOP applications under load

- Intrinsic safe: comply with hazardous environments

- Compact, lightweight, robust and weather-resistant

- PLC system integration

Are you interested in our products?

Register to Fluid-Hub.net, the digital portal for our products, and discover the online range.

Access Fluid-Hub.net, get an extra 2% discount, and many other benefits.

Why Your Fluid Mate?

Specialized technical support

We are at your support from the verification to the implementation of tailor-made diagrams and solutions

Automated warehouse

To monitor the order flow with precision, accuracy and speed

Wide range of products

We offer you multiple alternatives to quickly meet your request

Testing

We test the quality and parameters of the product you have chosen